|

Atlantic Coast S Gaugers - ACSG

"Promoting S Gauge along the East Coast" |

|

|

Atlantic Coast S Gaugers - ACSG

"Promoting S Gauge along the East Coast" |

|

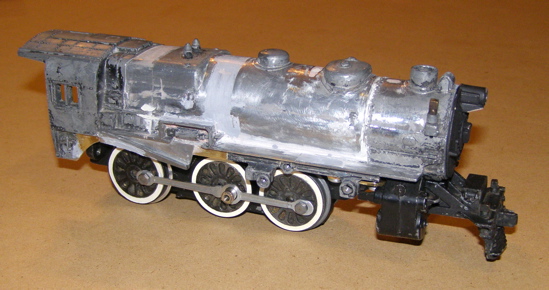

Pennsylvania 4-6-0 G-5

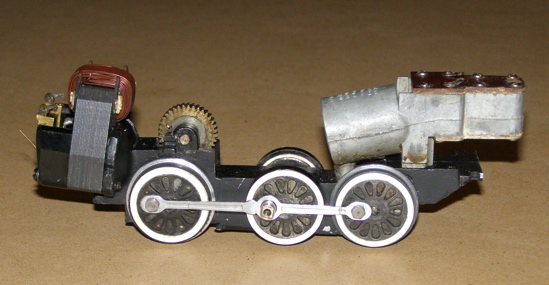

The K-5 type drive rods and eccentric rods had to be shortened to fit this locomotive. The tender is a Gilbert Atlantic-type tender that resembles the type used on many of the Pennsylvania G-5 locomotives. I used S-Helper Service tender trucks for this locomotive.

These views also show how the motor protrudes from the cab. One-quarter inch was removed from the plastic rear section to shorten it. Otherwise the tender could not have been attached this closely to the locomotive.

A third cut had to be made behind the steam dome so that section of the boiler could be lengthened. A short section of copper pipe was cut and formed into an inverted "U" shape to fit inside the boiler to bridge the gap.

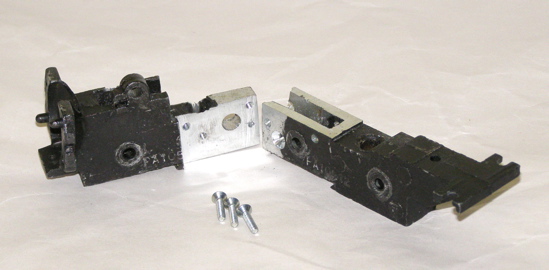

This picture also shows the brass sheeting I formed to attach the locomotive frame to the boiler. The front has a brass sheet attached to the original mounting holes. The Atlantic frame does not fit the same as the Pacific frame; the attaching points are narrower and farther forward so the mounting under the boiler had to be shifted forward. This brass sheet performs that function.

The rear of the frame rests on the brass strip I made to span the rear of the boiler.